We assembling and supply greatest scope of plate heat exchanger utilizing the most cutting edge innovation for a wide arrangement of heat move applications utilized in different enterprises, for example, substance industry, seaward, oil and gas, petrochemicals power plants, mash and paper, steel, zinc and aluminum, sugar, vegetable oil, bottling works/refineries, dairy/drinks and others.

Brazed plate heat exchangers

Our brazed heat exchangers offer customized answers for the best conceivable scope of utilizations Finned tubes supplier in Oman. On account of the robotized production and minimal plan of our brazed Arrangement, we can amass a modified heat exchanger in the most brief time conceivable. We pick among copper-and nickel-brazed or VacInox plate heat exchangers relying upon the field of use. We search for the most affordable arrangement from the different sizes and assorted frill accessible to us and adjust them unequivocally to your necessities with altered associations.

Gasketed plate type heat exchanger

Similarly as its name shows, a twofold plate plan. As opposed to utilizing single plates between the liquids this plan utilizes twofold plates to expand security. The plate pack comprises a bunch of twofold plates where each twofold plate has two indistinguishable plates stacked on top of one another and are consolidated by laser welds around the ports. A dainty air hole between the plates goes about as a wellbeing zone on the off chance that any of the two plates were to fall flat. In the event that any of the two liquids would spill through the primary plate it would be kept from going any further because of the air hole and the subsequent plate.

Completely welded plate heat exchanger

Combination reinforced plate heat exchangers are made of 100% tempered steel and give effective heat move a little impression. They are without upkeep and offer a long assistance lifetime. They are fit in applications which put appeal on neatness, applications where forceful media, for example, smelling salts are utilized or where copper and nickel defilement isn’t acknowledged. Can deal with high temperatures or incredibly high pressing factors. These heat exchangers are ideally utilized: Water frameworks with destructive media, sterile applications, high temperature applications.

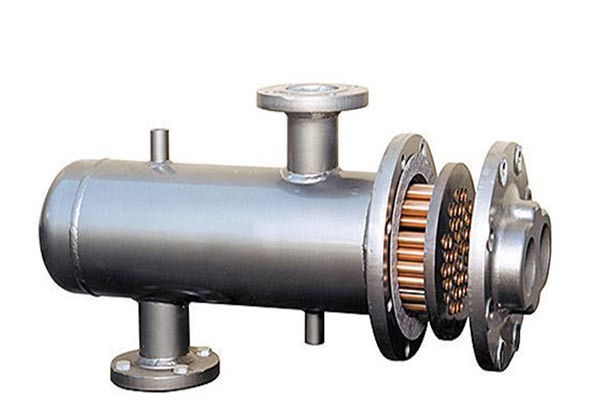

Shell and cylinder heat exchangers

The most widely recognized sort of heat exchangers, shell and cylinder heat exchangers are developed of a solitary cylinder or arrangement of equal tubes (i.e., tube pack) encased inside a fixed, tube shaped pressing factor vessel (i.e., shell). The plan of these gadgets is to such an extent that one liquid courses through the more modest tube(s), and the other liquid streams around its/their outside(s) and between it/them inside the fixed shell. Other plan qualities accessible for this sort of heat exchanger incorporate finned tubes, single-or two-stage heat move, countercurrent stream, concurrent stream, or crossflow courses of action, and single, two, or different pass setups.

A portion of the kinds of shell and cylinder heat exchangers accessible incorporate helical loop heat exchangers and twofold line heat exchangers, and a portion of the applications incorporate preheating, oil cooling, and steam age.

Twofold line heat exchangers

A type of shell and cylinder heat exchanger, twofold line heat exchangers utilize the least difficult heat exchanger plan and design which comprises at least two concentric, round and hollow lines or tubes (one bigger cylinder and at least one more modest tube). According to the plan of all shell and cylinder heat exchangers, one liquid moves through the more modest tube(s), and the other liquid streams around the more modest tube(s) inside the bigger cylinder.

The plan prerequisites of twofold line heat exchangers incorporate qualities from the recuperative and roundabout contact types referenced already as the liquids stay isolated and move through their own channels all through the heat move measure. In any case, there is some adaptability in the plan of twofold line heat exchangers, as they can be planned with concurrent or countercurrent stream courses of action and to be utilized separately in arrangement, equal, or arrangement equal designs inside a framework. For instance, Figure 4, underneath, portrays the exchange of heat inside a detached twofold line heat exchanger with a concurrent stream design.

Plate heat exchangers

Additionally alluded to as plate type heat exchangers, plate heat exchangers are built of a few slim, rigid plates packaged together. Each pair of plates makes a channel through which one liquid can stream, and the pairs are stacked and appended—by means of blasting, brazing, or welding—with the end goal that a subsequent section is made between pairs through which the other liquid can stream. The standard plate configuration is likewise accessible for certain varieties, for example, in plate blade or pad plate heat exchangers. Plate blade exchangers utilize balances or spacers among plates and take into consideration different stream designs and in excess of two liquid streams to go through the gadget. Cushion plate exchangers apply strain to the plates to expand the heat move proficiency across the outside of the plate. A portion of different sorts accessible incorporate plate and edge, plate and shell, and twisting plate heat exchangers.

Other heat exchanger variations

Heat exchangers are utilized in an assortment of utilizations across a wide scope of enterprises. Thus, there are a few variations of heat exchangers accessible, each appropriate for the prerequisites and details of a specific application Heat exchanger manufacturer. Past the variations referenced above, different sorts accessible incorporate air cooled heat exchangers, fan cooled heat exchangers, and adiabatic wheel heat exchangers.